Summary

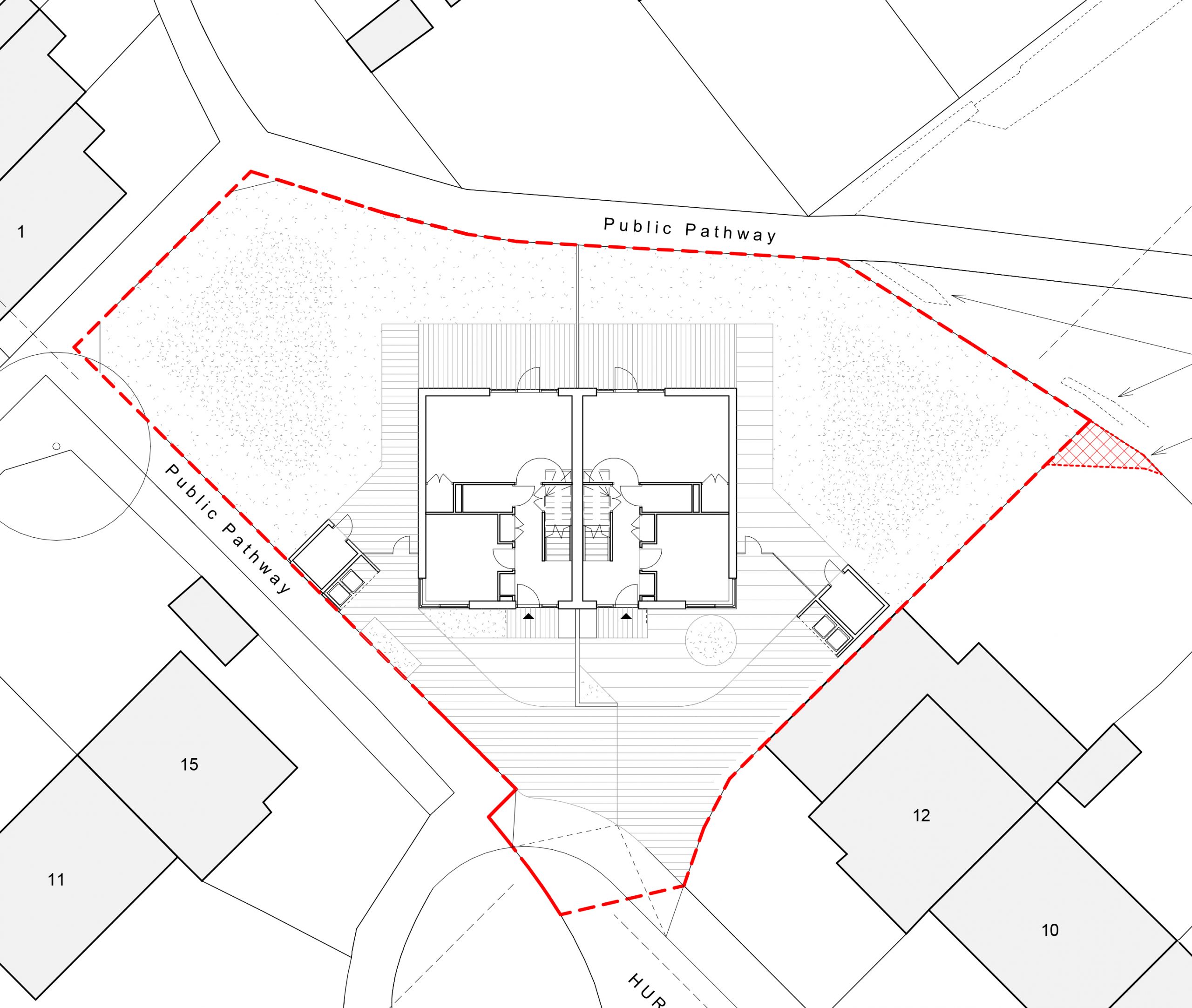

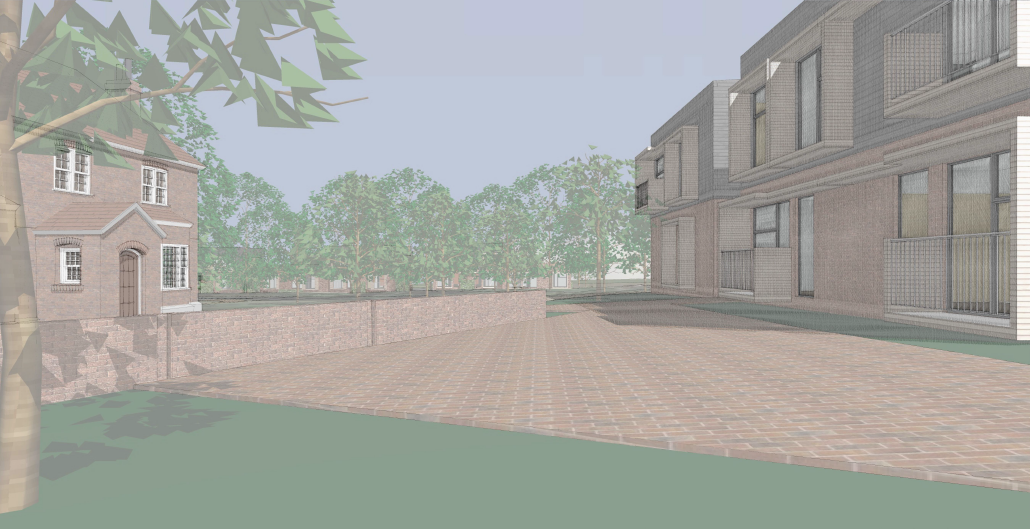

Springfield Meadows is a project of 25 high-performance homes, which provide comfortable, low-carbon living. Residents benefit from diverse shared outdoor spaces, including a wildlife pond, an orchard and private gardens.

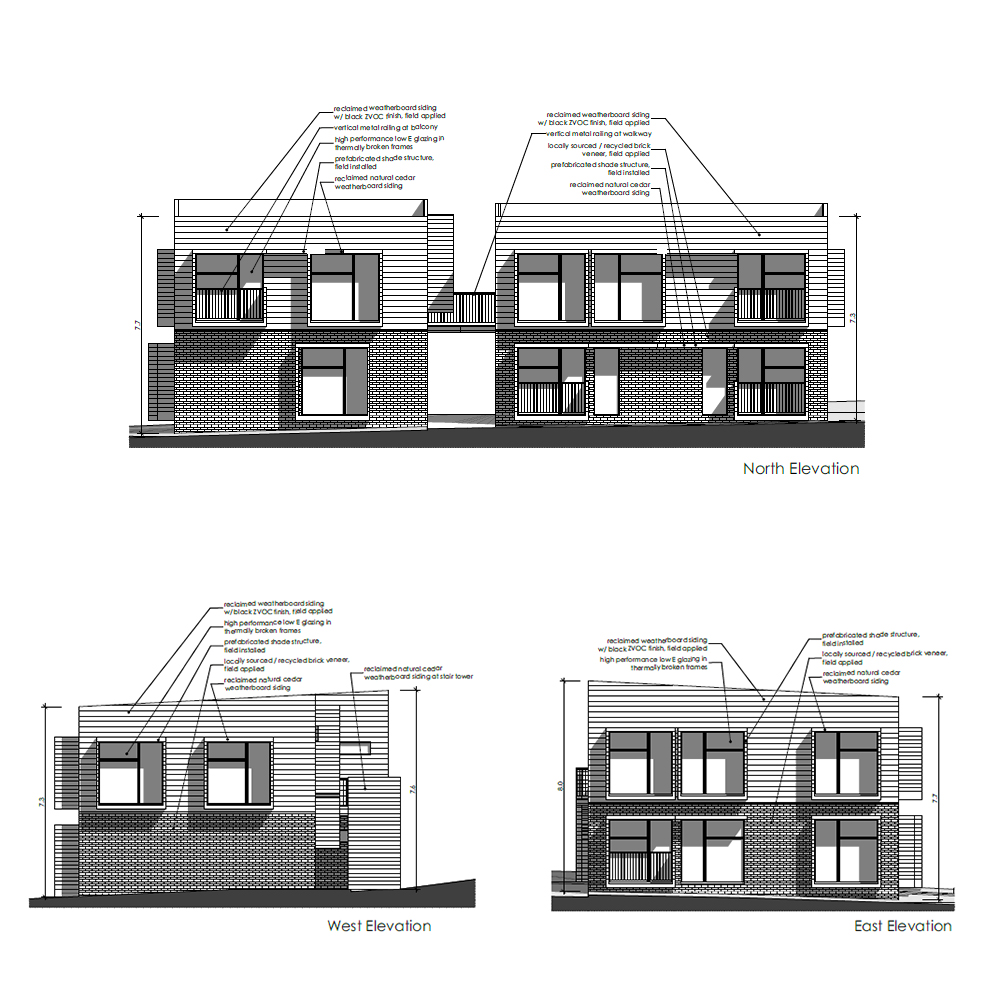

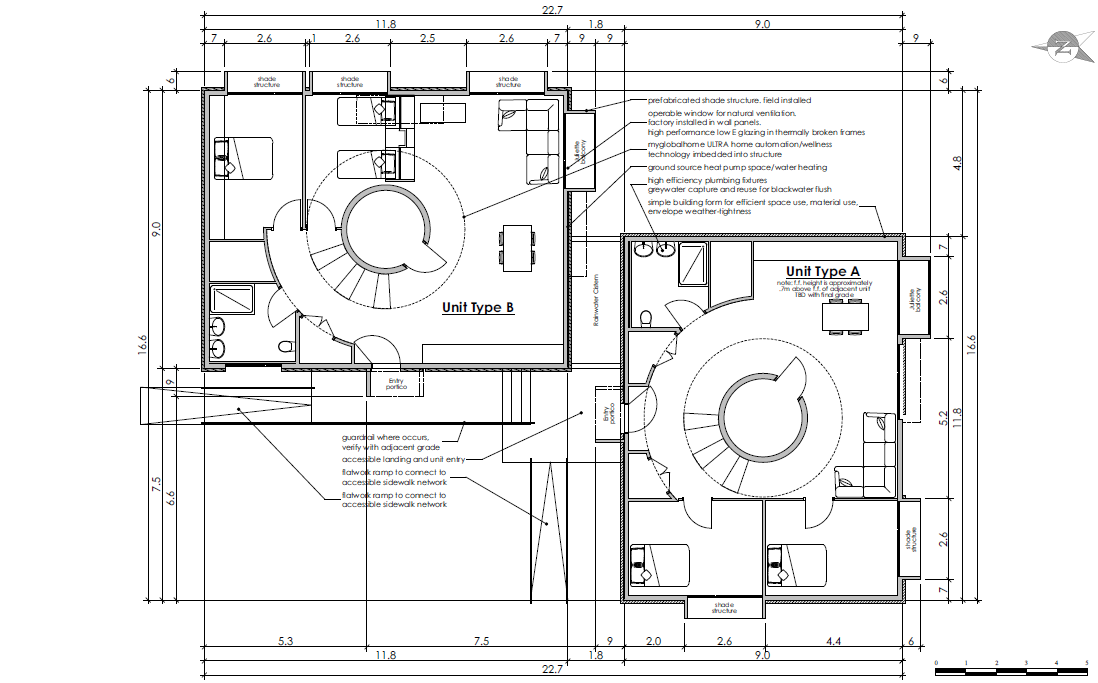

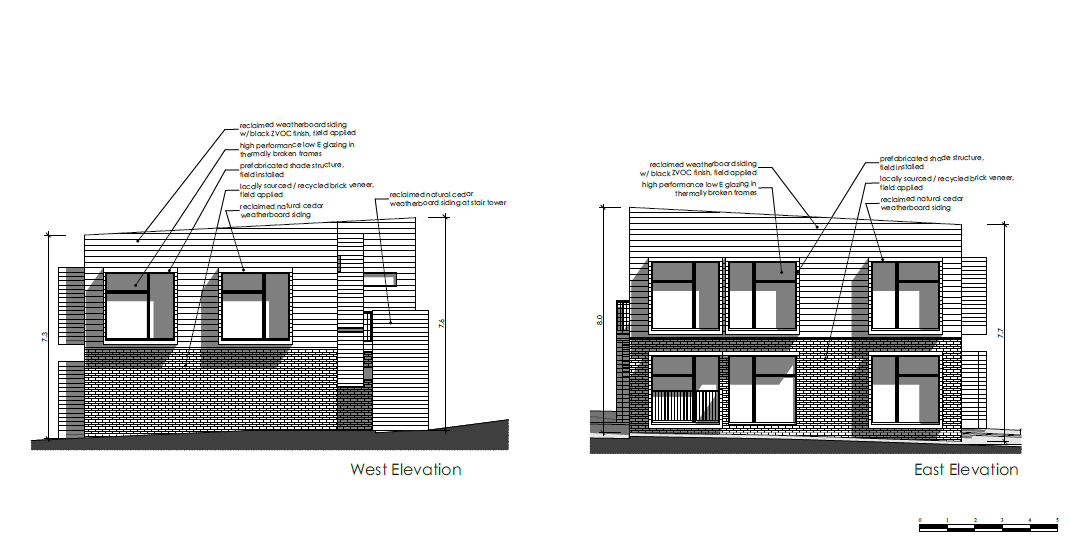

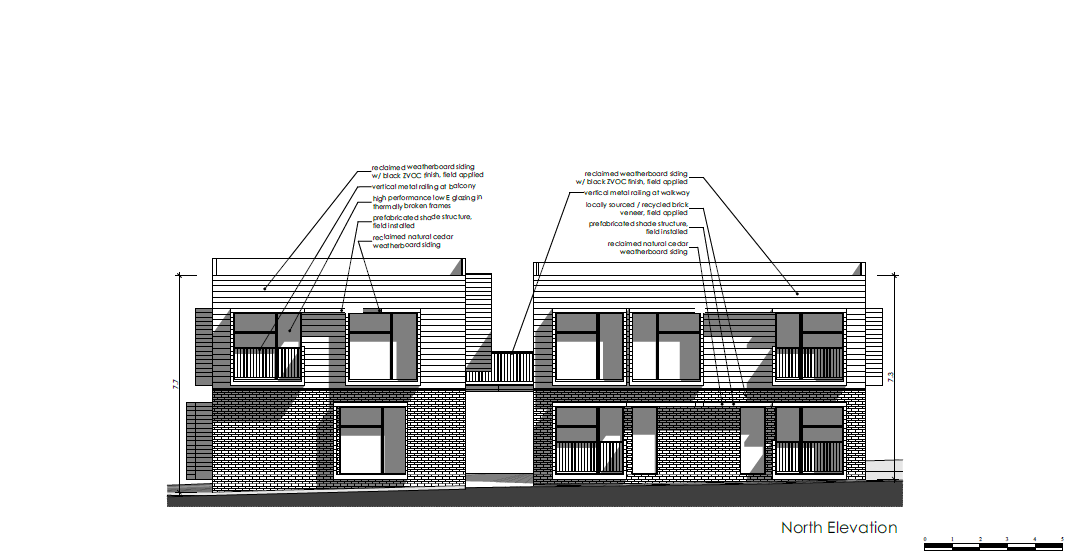

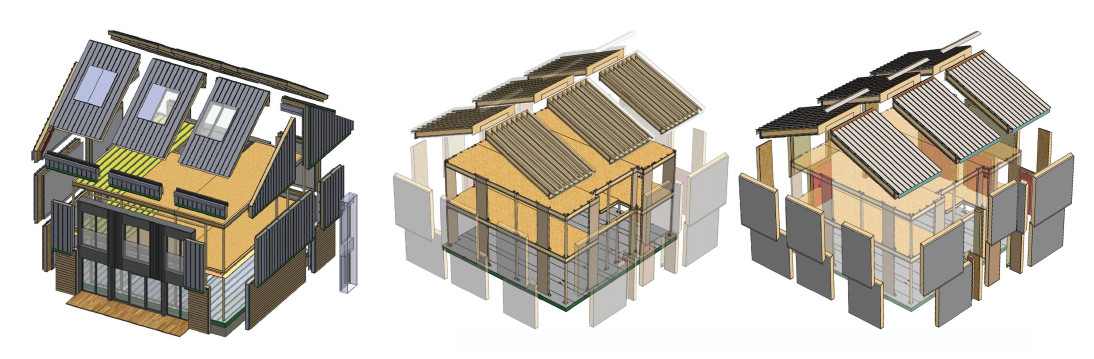

The design is guided by Passivhaus principles and constructed using the Biond system, an off-site manufactured, closed panel timber frame construction, insulated with Lime-Hemp and natural fibre insulation.

Springfield Meadows has been awarded One Planet Living Global Leader status by the leading environmental charity Bioregional.

Key information

- Client and developer: Ssassy Springfield Ltd

- Architects/designer and contractor: Greencore Construction Ltd

- Location: Southmoor, Oxfordshire

- Project type: New build

- Number of homes: 25

- Sector: 9 affordable homes, 16 private units

- Key dates: 18 units complete, full completion estimate December 2021

Key facts/highlights

- Zero embodied carbon

- Net-zero energy in use

- The second phase of the project locks up more carbon than it emits and generates more energy than it uses

- Awarded One Planet Living Global Leader status by Bioregional

- BBO Wildlife Trust partnership

- Elimination of gas utilities to create an all-electric development

- PV panels to make it net-zero energy

Energy performance

- Energy Use Intensity (EUI): Net zero in operation

- EPC rating: A

- Space heating demand: 15 kWh/m²/yr (Passivhaus), with ongoing monitoring

- Dwelling Fabric Energy Efficiency (DFEE): 42.3 kWh/m²/yr

- U values: 0.14 W/m²K (Passivhaus classic, uncertified)

- Air tightness: 0.6 ACH (Passivhaus classic, uncertified)

- MVHR installed

- Direct electric heating, hot water and cooking

- PV panels, are estimated to generate more electricity than used over the course of the year

Current monitoring is being undertaken with meter readings but the developers are about to put in place a detailed programme with a research institute to collect more detailed data.

Whole life carbon/resource efficiency

A whole life carbon assessment of the individual panels that the homes are constructed from has been undertaken, with a study of a ‘typical’ individual house being undertaken as of the writing of this case study, with results to be made available in the future.

Everything is designed so that it uses mechanical fixings that can be withdrawn to allow components to be reused or recycled.

Some houses incorporate smart technology (specified by the clients so there are various price points), with the aspects that link into energy control and energy monitoring considered for future projects.

The Bioregional One Planet Living sustainability framework was chosen as it considers the wider aspects of the development as well as carbon and energy.

Materials and construction

- Minimising the use of high energy materials including concrete and steel

- Use of cross-laminated timber for the upper floors (and any flat roofs). These lock-up 125kg of CO²e/m² of floor

- Cellulose insulation in the roofs

The project makes use of Biond Building System, a closed panel timber frame that is insulated with Lime-Hemp and wood-fibre insulation. The external wall panels lock up 32kg of CO²e/m² per wall. The following link is the output from a Bath University Research project on the system.

https://www.biond.co.uk/wp-content/uploads/biond_laymans-guide.pdf

EV charging

Each dwelling has a provision for two EV charging units.

Access to green space and amenities

Over an acre of shared space including a wildlife pond and an orchard.

Nature and biodiviersity

Developers worked with Berkshire Buckinghamshire Oxfordshire Wildlife Trusts to design the public open spaces and all landscaping for biodiversity gain. This is part of the One Planet Living action plan that arose out of considerations for the nature and biodiversity on the site. The BBO WIldlife Trust advised on the design phase and are carrying out monitoring for the next 5 years.

Scalability/buildability

The panelised Biond system is pre-fabricated and lends itself to fast onsite construction at any chosen scale. For a normal house, erection on site can be carried out within a few days, with the aim to deliver a weather-tight superstructure in three weeks.

Further links and information

Case study kindly funded by MCS Charitable Foundation