Summary

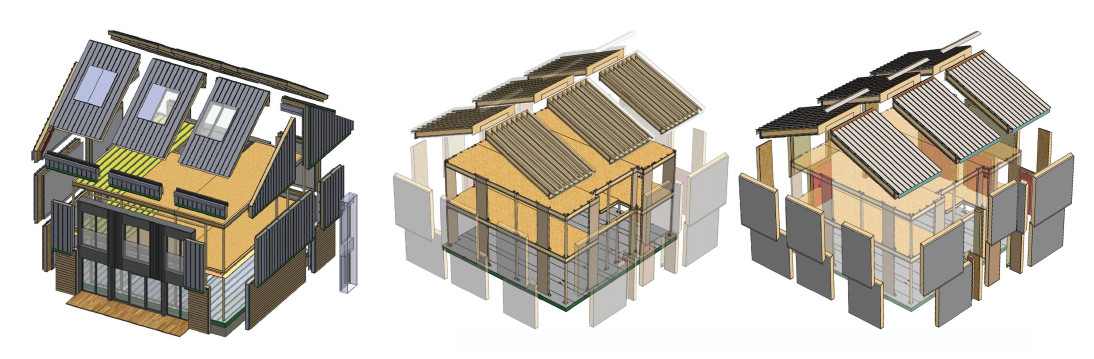

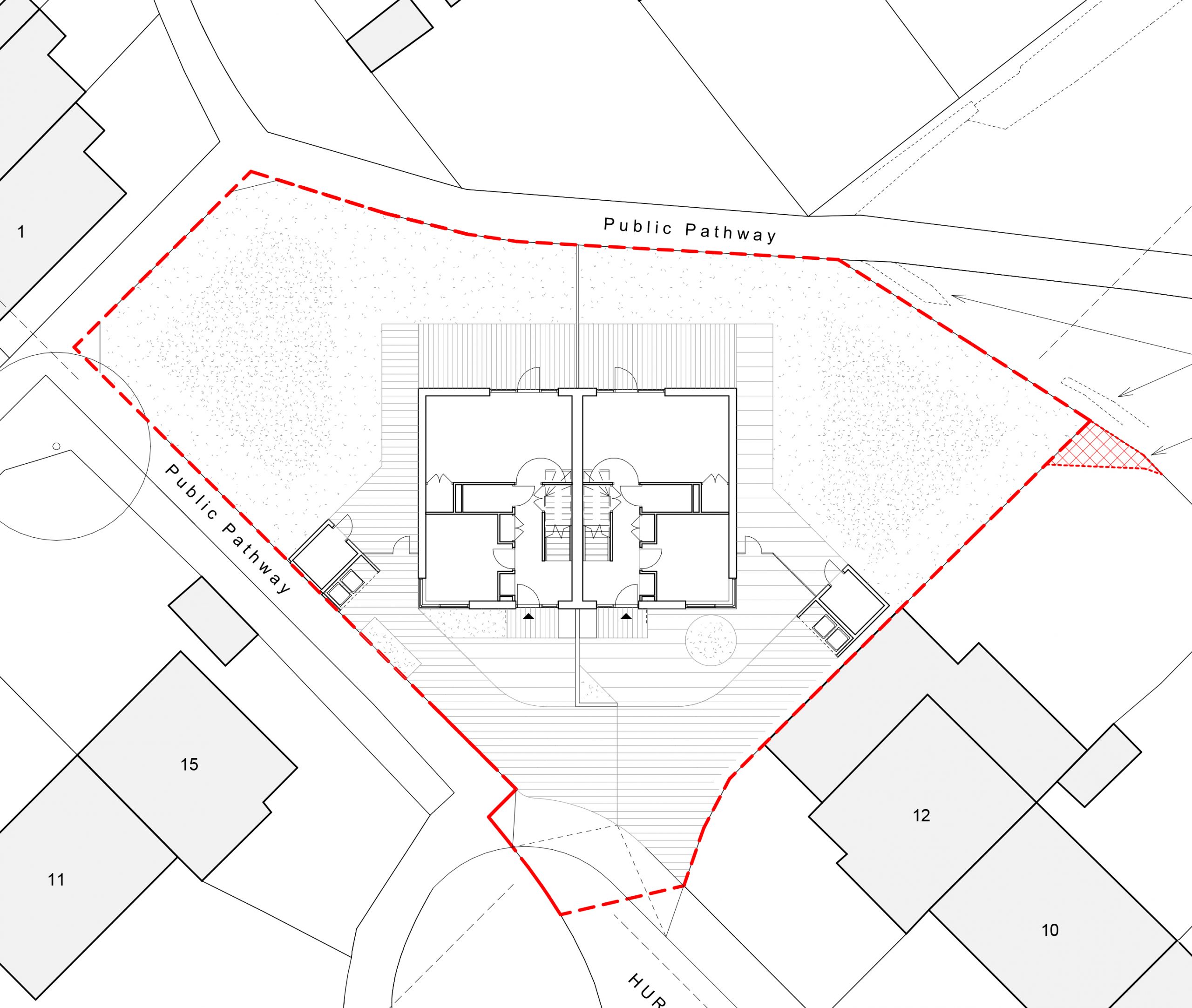

A demonstration project of two ‘flat pack’ homes built using a standardised platform kit-of-parts, delivered to site without the need for a heavy goods vehicle and assembled by a semi-skilled and diverse contractor team.

The 3-bedroom homes have been designed and built to achieve Passivhaus standards (uncertified), to be maintenance-free externally for thirty years, have low running costs and be available for social affordable rent.

The project was one of several small-scale projects commissioned by the London Borough of Ealing who were seeking to explore a range of MMC solutions.

Key information

- Client: Ealing Council

- Developer: Buildeco Offsite Architecture

- Sub-contractor: B-Line

- Architects: C.F.Moller Architects UK

- Location: Northolt, Ealing

- Engineers/consultants: Conisbee Consulting Engineers, XCO2 Energy, Butler & Young Associates (M&E)

- Panel Manufacturer: GMOC

- Project type: New-build

- Number of homes: 2

- Sector: Social Housing

- Key dates: Handover – 16th November 2020

Key facts/highlights

- Whole life carbon calculation of the building taken from the extraction of raw materials through to manufacturing, transport, assembly, operational use, end of life and disassembly

- At the end of the buildings life, the system is reconfigurable to form other types of buildings

- Fabric first approach with Passivhaus principles (not certified)

- Reduced foundation costs, due to lighter building weight

- Building assembled within ± 1mm

- Site assembly by hand by a diverse, trained, multitask workforce

- Delivered entirely in ‘white vans’, removing use for an articulated lorry

- Achieved EPC ‘B’ without renewables, with renewables has the potential to achieve EPC ‘A’

Energy performance

- Energy Use Intensity (EUI): 53 kWh/m²/yr

- EPC rating: B

- Space heating demand: 22.7 kWh/m²/yr

- Dwelling Fabric Energy Efficiency (DFEE): 42.3 kWh/m²/yr

- U values:

- Roof – 0.14 W/m²K

- Ground floor – 0.13 W/m²K

- Suspended floor – 0.16 W/m²K

- Walls – 0.14-0.15 W/m²K

- Door – 0.45 W/m²K

- Windows vary between 0.8-1.6 W/m²K, g-value 0.52-0.64

- The tenant reported that to date their monthly bill in the coldest winter month was just £23

- MVHR installed

Whole life carbon/resource efficiency

- The buildings can be disassembled at end of life, with panels being able to be reused and reconfigured. It is designed in such a way it can be disassembled in reverse order

- Use of MMC to minimise material waste

- Carbon reductions of between 30-50% were achieved due to the lightweight structure requiring shallower foundations and fewer site deliveries

- Only 2 skips were used for waste material throughout project delivery

Materials and construction

The UK manufactured panels of the build system are constructed from non-combustible materials, Light Gauge Steel (LGS) & Magnesium Oxide boards (MgO boards), and the assembly of the panels is within ± 1mm and the overhaul dimensions of the building when assembled is within ± 2mm in all directions.

- Floor, walls, ceiling and roof panels are almost identical

- The building components do not use any nuts, bolts or screws and the whole building is assembled using one tool

- To assemble the full superstructure from ground level to roof took a total of 28 man-days in three phases

EV charging

There is provision for a 32amp single phase charging point.

Thermal comfort and resilience

- CIBSE TM52 compliance

- Energy-efficient lighting

- Solar control glazing

Access to green space and amenities

- 120/150m² private rear gardens

- 250m to the local bus stop

- Shops within walking distance

Safety and security

The scheme complies with Secured by Design.

Scalability/buildability

The system is a standardised and is scalable using Panelised MMC category 2 (Pre-Manufacturing – 2D primary structural systems), which can then be designed to any size.

Quotes

David Baptiste, Head of Housing Development, Ealing Council

“The project was completed to a high quality build and energy standard which is endorsed both by the development department and residents living in the accommodation.”

Robert Turner, Project Officer, Ealing Council

“The Quality of the finished produce was excellent – better than the other demonstration projects, it achieved the promised thermal performance, the buildings are contemporary and attractive, and they are constructed from materials and using techniques that will minimise long term maintenance.”

Further information and images

Case study kindly funded by MCS Charitable Foundation